Steel Specimens

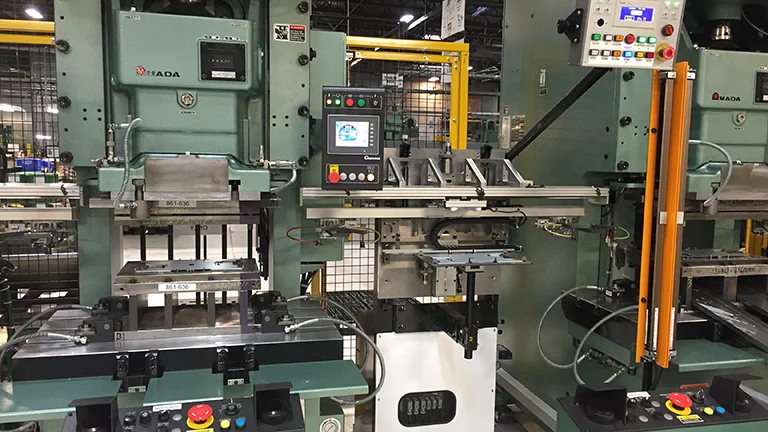

Oneda Corporation, a full-service metal stamping manufacturer, complete with machine shop, tool and die shop, and design/engineering services out of Columbus, Georgia, recently decided to look for new opportunities to expand their customer base. The company sent Michael Brooks, manager, to a Georgia Tech Contracting Academy class, to learn more about opportunities to bid on and win government contracts.

Once the class commenced Brooks was quick to register Oneda as a federal and state contractor. Within a few short months, Robert Amaro, owner of Advanced Materials Testing & Technologies (AMTT), an engineering consulting firm in Alabama, reached out to him for assistance on a project.

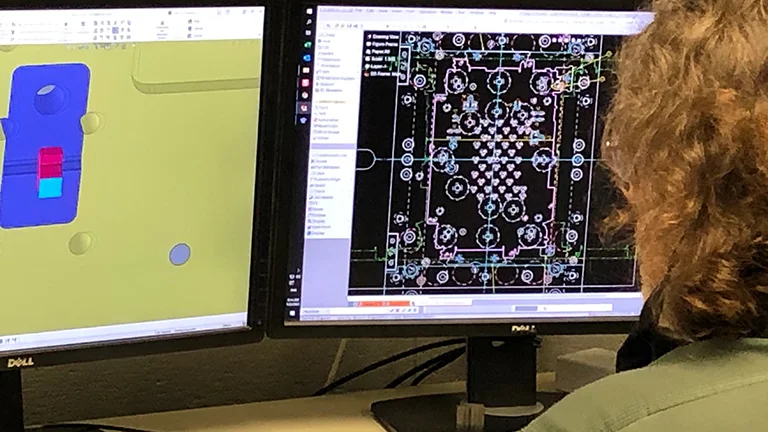

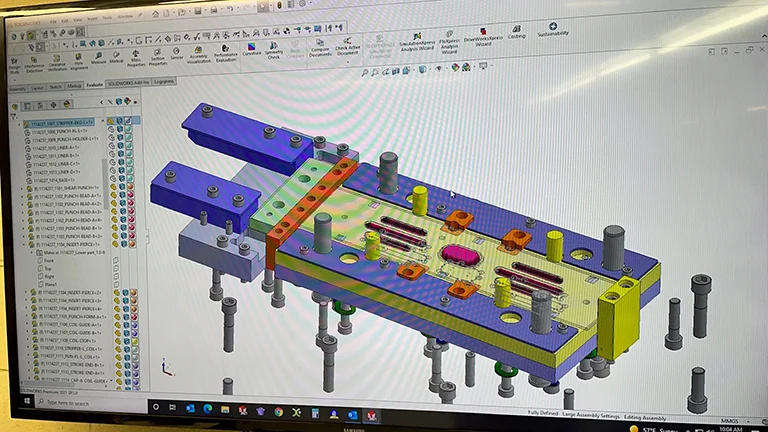

AMTT, in conjunction with the not-for-profit research institute Southern Research, was awarded a federal grant to support gas and electric utility companies by researching the possibility of extending the useful operational lives of existing coal plants throughout the U.S. As part of the project, Amaro received very large, organically shaped, steel weldments from shuttered coal plants to further test and analyze the material. The steel received needed to be processed into precise cylindrical specimens extracted from exact positions within the base material, weld heat affected zones, and weld fusions zones, all while maintaining traceability relative to specimen position and orientation within the original organic weldment. AMTT went through the government contracting process to find a third-party supplier that could assist in this endeavor.

Amaro began working with Brooks and the Oneda team, first visiting the Oneda plant to get a broader understanding of their capabilities. Through this visit and the subsequent agreement of a partnership, AMTT sent the material to Brooks, who then worked with his skilled tool and die makers to create the required jigs and fixtures to extract the specimens following AMTT’s exacting specifications by use of their Wire EDM machine. Given the timing of the project relative to COVID (August/September 2020) and the resulting delay in the project presented by COVID, AMTT and Southern Research needed more than a machine shop to perform this work. The services of Oneda’s design team, tool and die shop, and administrative department were all required as full project team members in order to support the federal grant. Since both companies were in the Southeast, the start to finish lead time was two weeks, half the time of what AMTT was being quoted from other manufacturers.

Since this project, Oneda has received additional jobs through their government contracting number and are also in discussion with AMTT on future projects.