Metal Stamping

From prototyping initial designs to full mass production, our precision metal stamping capabilities consistently produce extremely precise and high-quality products for our customers.

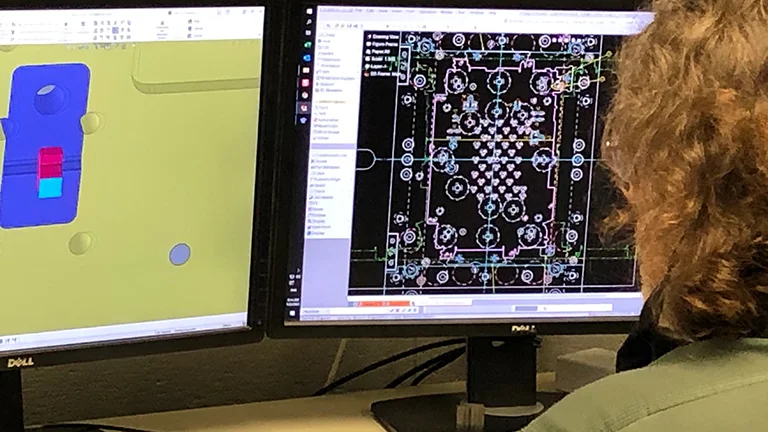

Advanced Engineering

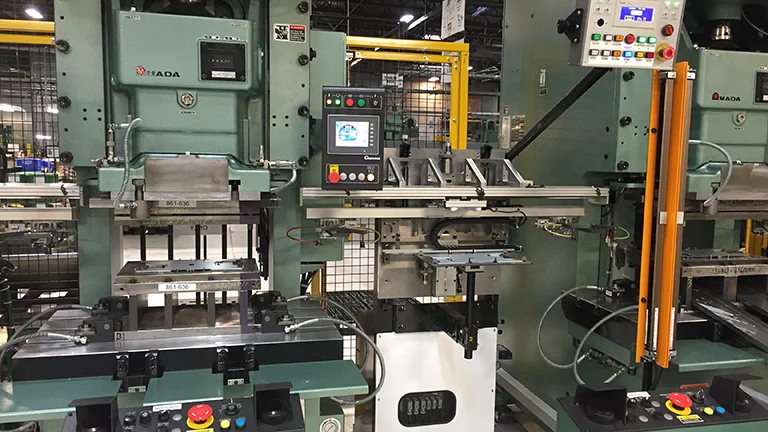

Using advanced engineering and design experience, we design and develop manufacturing techniques in automation by way of robotic transfer.

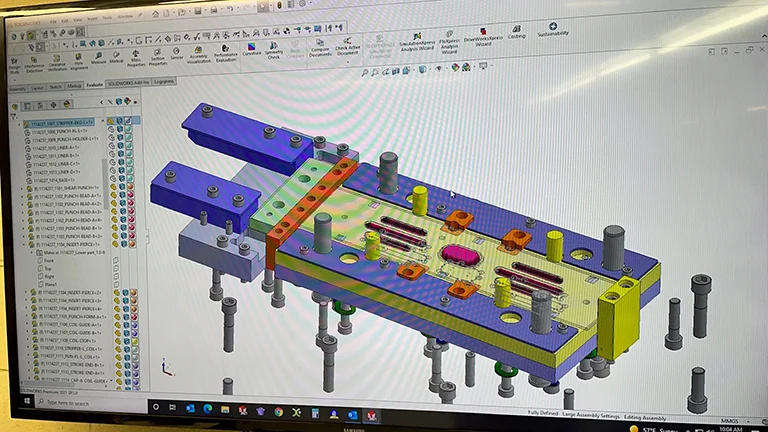

Tool and Die

Our team is comprised of highly skilled tool and die shop makers that pair traditional methodologies with advanced manufacturing capabilities.